Calculations follow commonly used HSE practices. Always confirm with your organization’s definitions and local regulations. References: OSHA 1904, ISO 45001, ILO OSH.

Checklist Inputs

Fill the form, preview, and export to PDF.

Session

Inductees Roster

| Name | Designation | Company | Remove |

|---|

Induction Topics

PPE Issued / Verified

Emergency Information

Permits / Authorizations

Documents Verified

Site Tour Items

Notes

Safety Induction Checklist

Generated preview — review and export to PDF

Generated On

Company: —

Conducted by: —

Project / Site: —

Date & Time: —

Language

—

Topics Completed

0

Acknowledged

No

Induction Topics Covered

PPE Issued / Verified

Emergency Information

Permits / Authorizations

Documents Verified

Site Tour Items

Inductees Roster

| Name | Designation | Company |

|---|

Notes

—

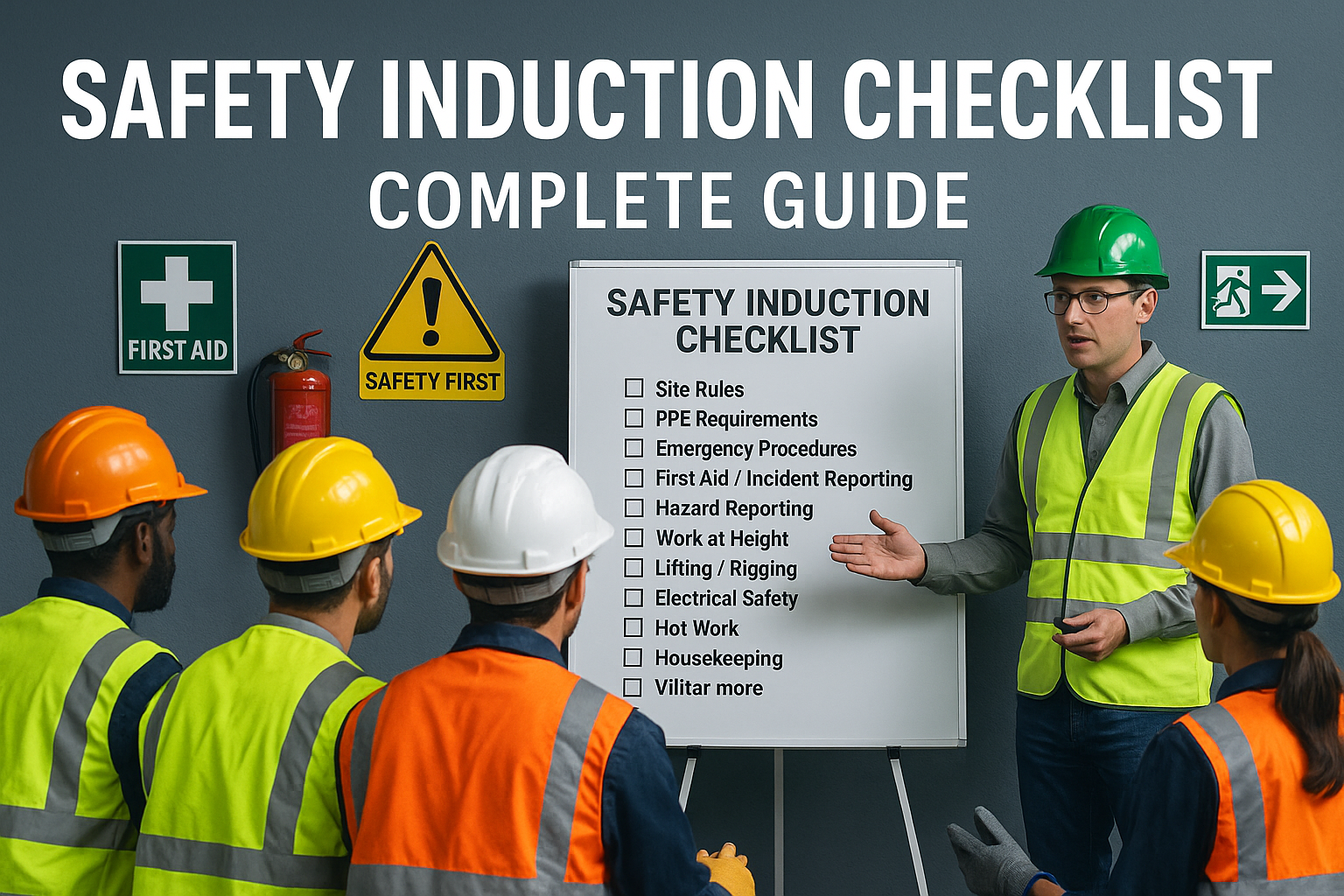

🧰 Safety Induction Checklist – Complete Guide

Every new worker stepping onto a site or into a facility faces unfamiliar hazards. From PPE requirements to emergency protocols, proper induction ensures they are fully aware of workplace risks before beginning work. A Safety Induction Checklist acts as a structured guide to introduce employees, contractors, and visitors to essential safety rules, procedures, and expectations.

This not only prevents accidents but also ensures compliance with legal requirements under OSHA, ISO 45001, ILO, and national safety laws.

✅ What Is a Safety Induction Checklist?

A Safety Induction Checklist is a structured document used by safety officers, supervisors, or HR departments to confirm that all key safety topics have been covered during induction training.

It typically includes:

- General site rules and responsibilities.

- PPE usage and mandatory requirements.

- Emergency procedures and first aid arrangements.

- Key hazard awareness (working at height, hot work, lifting, electricity, confined space).

- Security, welfare, and environmental requirements.

⚠️ Note: The checklist records the induction process but does not replace detailed risk assessments (HIRA, JSA).

📋 Key Components of a Safety Induction Checklist

A comprehensive induction checklist should cover the following modules:

- General Information → Name, company, role, start date, supervisor.

- Site Rules & Access → Entry/exit, restricted areas, ID badges.

- PPE Requirements → Hard hat, gloves, safety shoes, goggles, harness (as required).

- Emergency Preparedness → Evacuation routes, muster points, alarms, fire extinguishers.

- First Aid & Incident Reporting → Location of first aid kits, reporting procedures, stop-work authority.

- Work Hazards Overview

- Work at Height basics

- Lifting & Rigging

- Electrical/LOTO

- Confined Space Awareness

- Hot Work & Fire Safety

- Housekeeping & Waste → Keeping site clean, spill management, waste disposal.

- Environmental & Security → Noise, dust, emissions, site security procedures.

- Welfare Facilities → Restrooms, drinking water, cafeteria, rest areas.

- Acknowledgment & Sign-Off → Worker and supervisor signatures.

🛠 How to Use the Safety Induction Checklist

- Fill in Details → Worker’s name, company, role, induction date, trainer’s name.

- Cover Each Module → Supervisor explains each safety topic.

- Mark Completion → Tick ✅ Completed or ❌ Pending.

- Add Notes → Trainer records hazards discussed, special requirements, or additional instructions.

- Sign-Off → Worker acknowledges understanding, supervisor confirms completion.

- Store Records → Keep a digital/PDF copy for audits and compliance.

💡 Pro Tip: Use digital induction checklists with auto-PDF export for efficiency and proof of compliance.

📊 Example Usage

Example 1 – Construction Site

- Findings: Workers unfamiliar with evacuation siren.

👉 Action: Conducted live evacuation drill before work began.

Example 2 – Factory Induction

- Findings: PPE compliance low, workers unaware of MSDS for chemicals.

👉 Action: Provided PPE kits, conducted chemical handling training.

Example 3 – Office/Corporate Induction

- Findings: Staff unaware of AED and first aid kit locations.

👉 Action: Orientation tour conducted, AED signage improved.

📌 Why Is a Safety Induction Checklist Important?

✔ Ensures all new workers understand workplace hazards.

✔ Meets compliance with OSHA, ILO, and ISO standards.

✔ Reduces risk of accidents from lack of awareness.

✔ Improves worker confidence and safety culture.

✔ Provides documented proof during audits or inspections.

🏢 Real-World Applications

- Construction Projects → New contractors inducted before site entry.

- Factories & Plants → Induction before shift starts for new employees.

- Offices & Corporates → Fire safety, emergency, and welfare induction.

- Oil & Gas / High-Risk Industries → Mandatory induction before site access.

🔍 Common Mistakes in Induction Training

❌ Rushing the induction to “save time.”

❌ Treating checklist as paperwork only (not interactive).

❌ Using the same checklist for all sites without customization.

❌ Failing to include sign-off and record-keeping.

📌 Best Practices for Effective Induction Checklists

✔ Customize checklist to suit site-specific risks.

✔ Include both theory (rules) and practical (tours, demos).

✔ Make induction interactive with Q&A.

✔ Assign responsibility for follow-ups.

✔ Review and update checklists regularly.

❓ Frequently Asked Questions (FAQ)

Q1: How long should safety induction take?

→ Typically 1–2 hours depending on site complexity.

Q2: Who conducts safety induction?

→ Safety officers, supervisors, or HSE trainers.

Q3: Is induction mandatory for short-term contractors?

→ Yes, even visitors and temporary staff must undergo induction.

Q4: Can induction be done online?

→ Yes, but site-specific hazards must be covered in person.

🎯 Final Thoughts

A Safety Induction Checklist is not just a form—it is a safety gateway. It ensures that every individual on site is aware, prepared, and accountable.

By using our Safety Induction Checklist Tool, you can:

✔ Conduct structured inductions.

✔ Capture sign-offs and confirmations.

✔ Export auto-PDF induction records.

✔ Stay compliant with OSHA/ISO/ILO requirements.

💡 Pro Tip: Always integrate induction with HIRA, JSA, and PTW systems for a complete safety management framework.

👉 [Explore All Tools Here]

👉 [Open HIRA Generator]

👉 [Open JSA Generator]

External Links: