Calculations follow commonly used HSE practices. Always confirm with your organization’s definitions and local regulations. References: OSHA 1904, ISO 45001, ILO OSH.

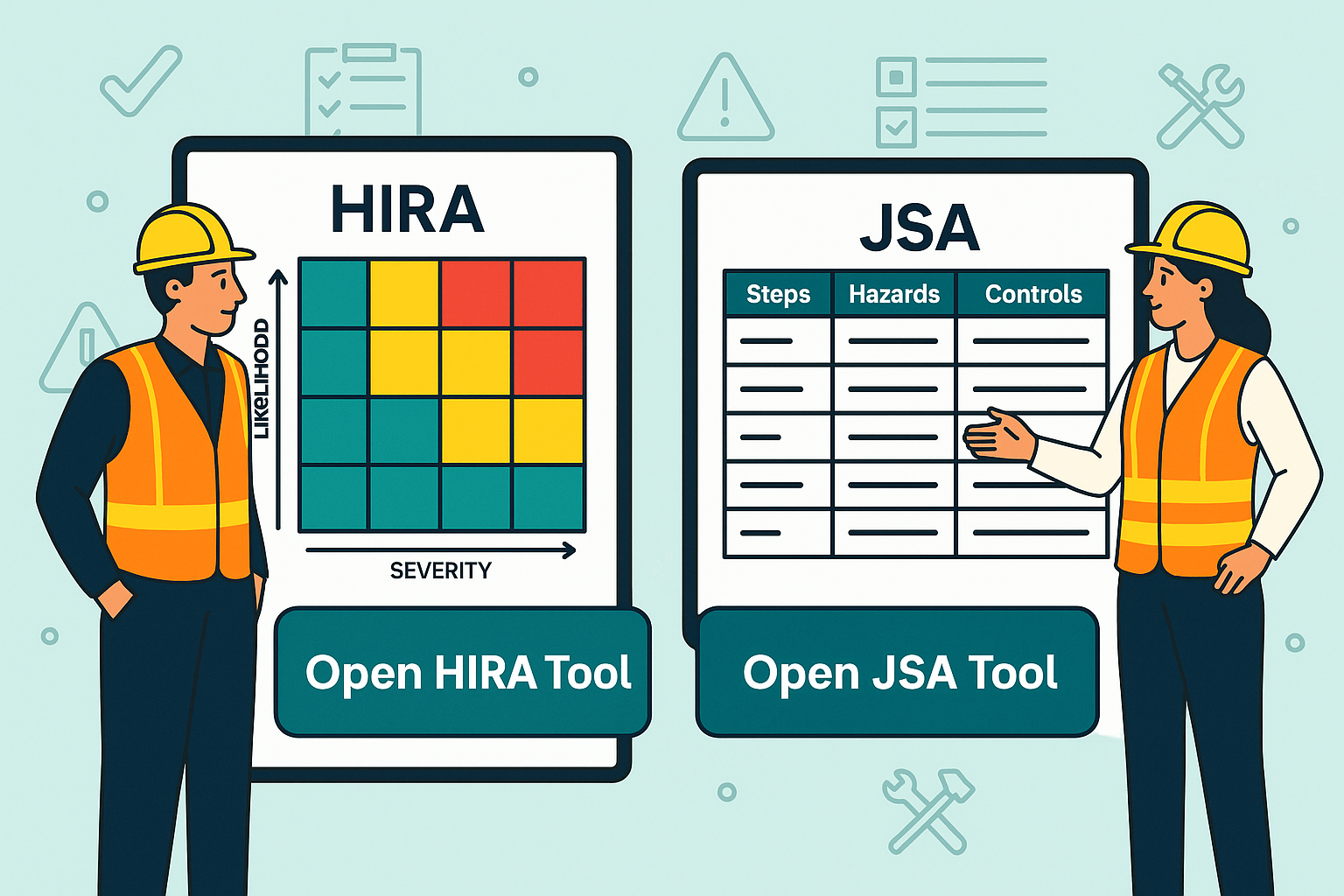

📝 Open HIRA and JSA Tools – The HSE Tools

🎯 Quick Access

👉 Open HIRA Tool

👉 Open JSA Tool

In high-risk industries such as construction, manufacturing, oil and gas, mining, and heavy engineering, managing workplace hazards is not just a legal requirement but also a moral responsibility. Every activity—whether lifting, excavation, welding, or working at height—has the potential to expose workers to accidents, injuries, or even fatalities.

To proactively manage these risks, organizations use Hazard Identification & Risk Assessment (HIRA) and Job Safety Analysis (JSA). Both are internationally recognized safety management tools that help identify hazards, evaluate risks, and implement controls before work begins.

The Open HIRA and JSA Tools on The HSE Tools platform make it easier for safety officers, supervisors, and project managers to prepare structured, audit-ready safety documents instantly.

This article will guide you through what HIRA and JSA are, how they differ, why they are important, and how our free online tools can help you simplify and standardize the process.

✅ What Is HIRA (Hazard Identification & Risk Assessment)?

HIRA is a structured process of identifying potential hazards in a task, assessing the risks associated with them, and implementing appropriate control measures. It is commonly prepared before starting a project, activity, or operation.

🔹 Key Components of HIRA

- Task Description → Define the scope of work (e.g., “Erection of scaffold at 12m height”).

- Hazard Identification → Spot potential hazards (falls, dropped objects, electrocution, fire, etc.).

- Risk Evaluation → Assess severity and likelihood using a risk matrix.

- Control Measures → Suggest engineering, administrative, or PPE controls to reduce risks.

- Residual Risk → Determine the risk after controls are applied.

🔹 Example of HIRA in Construction

- Task: Excavation for pipeline installation.

- Hazards: Cave-ins, underground utilities, equipment movement.

- Controls: Shoring, barricading, CAT scan before digging, banksman for equipment.

- Residual Risk: Low, if controls implemented.

💡 Pro Tip: Always review and update HIRAs when site conditions change.

✅ What Is JSA (Job Safety Analysis)?

JSA is a task-specific document that breaks down a job into sequential steps, identifies hazards at each step, and defines safe methods to perform the work.

🔹 Key Components of JSA

- Job Details → Site, task name, date, supervisor.

- Step-by-Step Breakdown → List each action in sequence.

- Hazards per Step → Identify risks (e.g., sparks during welding, slips during lifting).

- Control Measures → Safe practices, permits, PPE requirements.

- Responsible Person → Assign accountability for safety at each step.

🔹 Example of JSA for Hot Work

- Step: Prepare work area.

- Hazard: Fire risk from combustibles.

- Control: Remove flammable items, fire blanket, fire watch.

- PPE: Helmet, gloves, goggles.

- Responsible: Supervisor & Fire Watch.

💡 Pro Tip: JSAs should be briefed to workers before starting the job (toolbox talk).

⚖️ HIRA vs JSA – Key Differences

| Aspect | HIRA 📝 | JSA 📑 |

|---|---|---|

| Scope | Broad (project/activity level) | Narrow (specific job/task) |

| Purpose | Identify all possible hazards and risks | Break down tasks step-by-step for controls |

| When Prepared | Before project/activity begins | Before starting a specific job |

| Users | Safety officers, managers, planners | Supervisors, foremen, workers |

| Format | Matrix of hazards, risks, controls | Sequential job steps with hazards & controls |

💡 Think of HIRA as the big picture and JSA as the zoomed-in version of safety planning.

📌 Why Are HIRA and JSA Important?

✔ Legal Compliance → OSHA, ISO 45001, and ILO standards mandate risk assessments.

✔ Accident Prevention → Anticipates hazards before they cause harm.

✔ Audit-Ready Documentation → Essential during client, government, or third-party inspections.

✔ Worker Engagement → Involves teams in hazard awareness and control.

✔ Improved Safety Culture → Encourages proactive rather than reactive safety management.

🛠 Open HIRA and JSA – The HSE Tools

At The HSE Tools, we provide ready-to-use digital generators that make HIRA and JSA preparation simple, consistent, and professional.

🔹 HIRA Generator

Our HIRA Generator helps safety professionals:

- Enter job details (site, contractor, activity).

- List hazards, risks, and control measures.

- Automatically calculate risk levels (Low/Medium/High).

- Export a PDF report for records and audits.

🔹 JSA Generator

Our JSA Generator allows supervisors and engineers to:

- Select from templates (Excavation, Scaffolding, Hot Work) or start from scratch.

- Break down jobs into sequential steps.

- Add hazards, controls, PPE, and responsible persons.

- Export a professional JSA PDF instantly.

📊 Example Usage of HIRA and JSA Tools

Example 1 – Excavation Project

- HIRA Findings: Cave-in hazards, struck-by risks.

- JSA Findings: Step 1 – Barricading, Step 2 – Locate utilities, Step 3 – Shoring.

- Outcome: Work performed safely with zero incidents.

Example 2 – Scaffolding Work

- HIRA Findings: Falls, falling objects, unstable scaffold.

- JSA Findings: Step 1 – Erect standards, Step 2 – Install planks & guardrails, Step 3 – Tag inspection.

- Outcome: Scaffold certified safe before use.

Example 3 – Hot Work (Welding)

- HIRA Findings: Fire, fumes, burns.

- JSA Findings: Step 1 – Remove combustibles, Step 2 – Gas testing, Step 3 – Fire watch.

- Outcome: Fire incident prevented through strict controls.

📌 Benefits of Using Our Tools

✔ Free & Online → No software needed.

✔ Easy to Use → Fill in details, export in minutes.

✔ Audit-Ready → Professional PDF reports.

✔ Customizable → Edit templates to match company procedures.

✔ Mobile-Friendly → Access anywhere, anytime.

🔍 Common Mistakes to Avoid

❌ Copy-pasting old HIRAs and JSAs without updating site conditions.

❌ Ignoring worker input during preparation.

❌ Preparing documents but not briefing workers.

❌ Not reviewing after incidents or near-misses.

📌 Best Practices for Effective HIRA & JSA

✔ Conduct site walkdowns before preparing documents.

✔ Involve supervisors, workers, and contractors.

✔ Keep documents simple, specific, and practical.

✔ Review regularly and update as conditions change.

✔ Use digital tools like ours for consistency and accuracy.

❓ Frequently Asked Questions (FAQ)

Q1: Who prepares HIRA and JSA?

→ HIRA is usually prepared by safety officers or managers. JSA is often prepared by supervisors and discussed with workers.

Q2: How often should HIRA and JSA be reviewed?

→ HIRA: Before each new project or when major changes occur. JSA: Before starting each specific job or shift.

Q3: Can the same document be used across multiple sites?

→ No. Both HIRA and JSA must be site-specific and updated for conditions.

Q4: Are digital tools accepted during audits?

→ Yes. As long as they are signed/acknowledged, digital PDF records are fully audit-compliant.

🎯 Final Thoughts

The Open HIRA and JSA Tools provide safety professionals with a smarter, faster, and more reliable way to prepare critical safety documents.

By using them, organizations can:

✔ Save time.

✔ Improve accuracy.

✔ Engage workers.

✔ Stay compliant with OSHA/ISO/ILO standards.

Instead of struggling with manual spreadsheets or outdated templates, you can now generate professional, audit-ready HIRA and JSA documents with just a few clicks.

👉 [Explore All Tools Here]

👉 [Open HIRA Generator]

👉 [Open JSA Generator]

External Links :