Calculations follow commonly used HSE practices. Always confirm with your organization’s definitions and local regulations. References: OSHA 1904, ISO 45001, ILO OSH.

The Permit to Work Generator enables safety professionals to create work permits efficiently in 5 steps — covering hazard identification, LOTO, approvals, and documentation.

Permit Inputs

Fill sections below, preview, and export to PDF.

Project / Site

Load Template

Templates pre-fill relevant hazards, controls, PPE, isolations and gas tests (if applicable).

Note: What you need to prepare

- Work scope, exact location, and boundaries.

- Team members, supervisor, issuer/approver details.

- Isolation plan (electrical, mechanical, fluid, energy sources) and LOTO points.

- Hazards & specific controls (engineering, admin, PPE).

- Gas test results (for hot work / confined space) with instrument ID and times.

- SIMOPS conflicts and emergency arrangements.

Permit Details

Checklists

PPE Required

Isolations / LOTO

Gas Test

Hazards & Controls

| Hazard | Control / Precaution | Responsible | Remove |

|---|

SIMOPS & Emergency

Notes

Signatures (Names only)

Permit-to-Work (PTW)

Generated preview — review and export to PDF

Generated On

Permit No.: —

Work Type: —

Scope: —

Project / Site: —

Client: —

Location: —

Requestor: —

Supervisor: —

Issuer: —

Approver: —

Valid From: —

Valid To: —

Status: Open

Ensure all isolations, controls & PPE are in place before work.

PPE Required

Isolations / LOTO

Hazards & Controls

| Hazard | Control / Precaution | Responsible |

|---|

SIMOPS / Interface Controls

—

Emergency Arrangements

—

Additional Notes

—

Signatures (Names only)

Issuer (Permit Authority)

—

Receiver (Supervisor)

—

HSE Witness (optional)

—

📝 Permit to Work Generator – Complete Guide

A Permit-to-Work (PTW) system is a formal written procedure that ensures potentially hazardous work is properly authorized, documented, and controlled before it begins. PTWs are vital in industries like oil & gas, construction, power plants, and manufacturing, where multiple contractors and activities overlap.

By clearly defining scope, hazards, controls, and responsibilities, a PTW acts as a safety contract between the work crew and the issuing authority. Our Permit to Work Generator Tool makes this process digital, structured, and exportable as a PDF — ensuring compliance with OSHA, ISO 45001, ILO, and corporate HSE standards.

✅ What Is a Permit-to-Work (PTW)?

A Permit-to-Work is a documented authorization that specifies:

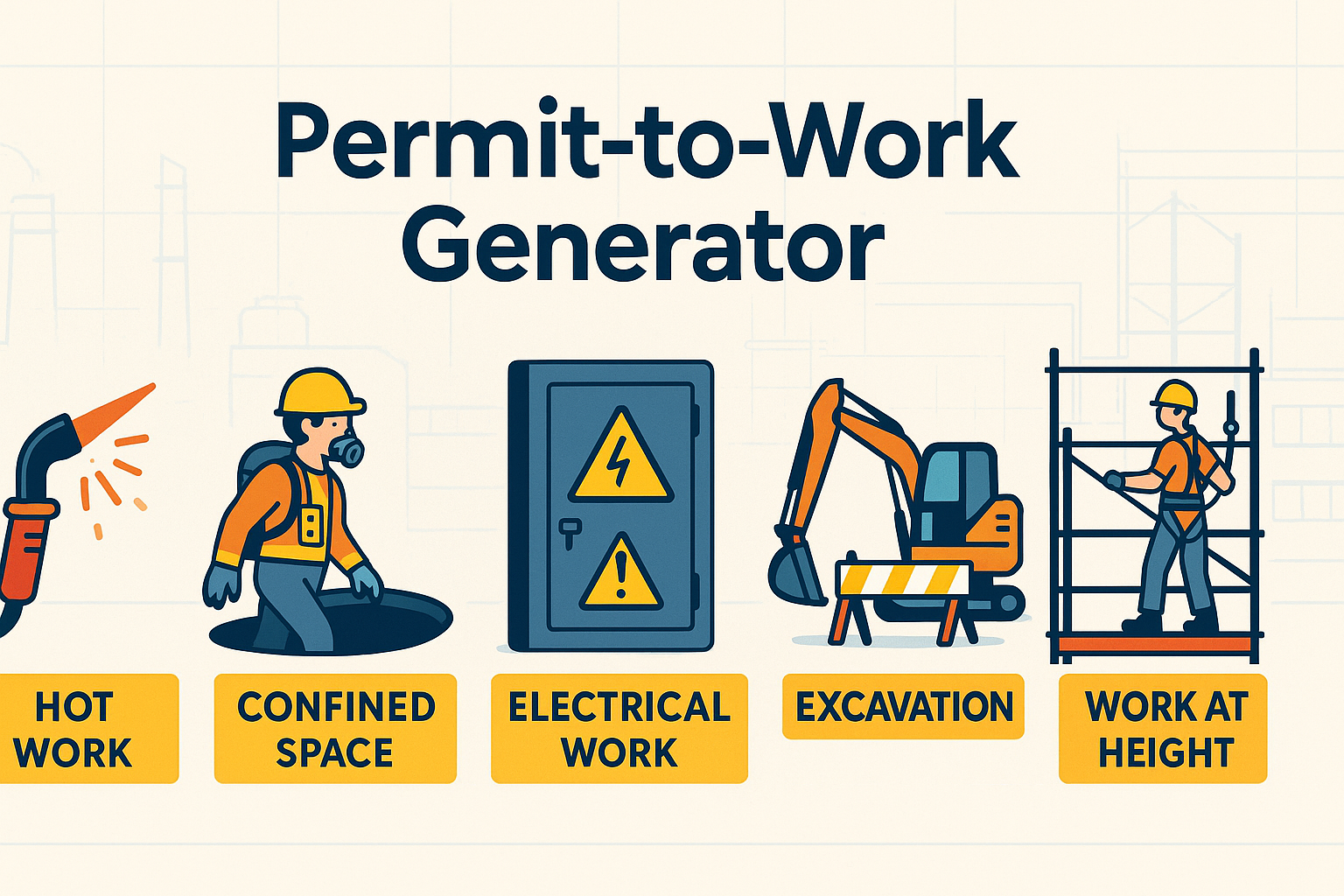

- Type of work (Hot Work, Confined Space, Electrical, Excavation, Work at Height).

- Job details (title, location, validity period).

- Hazards & controls to be applied.

- Isolation/LOTO requirements (lockout, tagging, gas testing).

- Authorized persons (issuer, receiver, crew).

- Signatures confirming understanding and accountability.

⚠️ Note: A PTW complements, but does not replace, detailed risk assessments (HIRA/JSA) and safe work procedures.

📋 Key Components of a PTW

A well-designed PTW should include:

- Job Details → Title, location, permit number, requested by, validity period.

- Hazards & Controls → Identified risks and corresponding mitigation.

- Isolation / LOTO → Electrical, mechanical, hydraulic, pneumatic isolation.

- Permit-Specific Requirements → Depending on type of work (Hot Work, Height, Electrical, Excavation, Confined Space).

- Gas Test (if Confined Space) → O₂, LEL, H₂S, CO readings.

- Authorized Persons → Workers, supervisors, permit authority.

- Signatures → Issuer, receiver, HSE witness.

🛠 How to Use the Permit to Work Generator

- Select Permit Type → Choose Hot Work, Confined Space, etc.

- Fill Job Details → Title, location, start & end time, requested by.

- List Hazards & Controls → Enter site-specific hazards and mitigation.

- Complete Isolation / LOTO → Check applicable lockout measures.

- Apply Permit-Specific Requirements → Hot Work → fire watch; Confined Space → gas test; etc.

- Add Authorized Persons → Name, role, company.

- Sign Off → Enter issuer, receiver, witness names.

- Validate & Export → Run validation → Download A4 PDF report with auto permit number and QR placeholder.

💡 Pro Tip: Use digital PTWs to avoid paperwork errors, ensure traceability, and speed up compliance audits.

📊 Example Usage for Permit to Work Generator

Example 1 – Hot Work Permit

Findings: Gas cylinders not properly secured.

👉 Action: Secured cylinders with chains, tested for leaks, fire watch assigned.

Example 2 – Confined Space Entry

Findings: O₂ at 18.5% (below safe threshold).

👉 Action: Ventilation applied until O₂ reached 20.9%. Entry postponed until clearance.

Example 3 – Electrical Permit

Findings: No arc-rated PPE available for switchgear maintenance.

👉 Action: Delayed work until PPE was issued; PTW revalidated.

📌 Why Is a PTW Important?

✔ Ensures hazardous work is controlled.

✔ Provides documented accountability.

✔ Prevents accidents from overlapping activities.

✔ Meets legal compliance with OSHA/ISO/ILO standards.

✔ Strengthens the safety culture across contractors & employees.

🏢 Real-World Applications

- Construction Projects → Hot work, excavation, lifting operations.

- Oil & Gas Facilities → Confined space entry, line breaking, electrical isolation.

- Factories/Plants → Machine maintenance, welding, painting, shutdown activities.

- Power & Utilities → Electrical switching, tower climbing, live-line work.

🔍 Common Mistakes in PTWs

❌ Treating PTWs as mere paperwork.

❌ Failing to validate hazards & controls.

❌ Allowing work to proceed with expired permits.

❌ Not updating PTW when conditions change.

❌ Lack of coordination between multiple permits (e.g., hot work & confined space together).

📌 Best Practices

✔ Digitize PTWs with auto validation & PDF reports.

✔ Customize templates per permit type & industry.

✔ Train all supervisors & contractors on permit rules.

✔ Use color coding & QR tracking for better visibility.

✔ Review permits daily and close them properly after work.

❓ Frequently Asked Questions (FAQ)

Q1: Who issues a Permit-to-Work?

→ Typically, a Permit Authority (PA) or supervisor authorized by the company’s HSE policy.

Q2: How long is a PTW valid?

→ Usually one shift (8–12 hrs), extendable upon review.

Q3: Is a PTW mandatory for all tasks?

→ No, only for hazardous or high-risk activities defined by company rules.

Q4: Can a PTW be reused?

→ ❌ No, each PTW is job-specific, time-bound, and must be reissued if conditions change.

🎯 Final Thoughts

A Permit-to-Work (PTW) is not just a form—it is a safety passport for hazardous jobs. By using our Permit to Work Generator, you can:

✔ Create structured permits in minutes.

✔ Validate inputs automatically.

✔ Export A4-compliant PDF reports.

✔ Ensure traceability with auto permit numbers & QR placeholders.

💡 Pro Tip: Always integrate PTWs with HIRA, JSA, and LOTO systems for a complete safety management framework.

👉 [Explore All Tools Here]

👉 [Open HIRA Generator]

👉 [Open JSA Generator]

External Links: